Solar power: Automated development of materials for solar cells

Thanks to high-throughput experiments and machine learning, FAU researchers are accelerating the search for chemical compounds for high-performance elements.

A team of researchers from Friedrich-Alexander-Universität Erlangen-Nürnberg (FAU), the Helmholtz Institute Erlangen-Nürnberg for Renewable Energy (HI ERN) and the Karlsruhe Institute of Technology (KIT) have developed a closed process for finding optimal high-performance materials for perovskite solar cells (PSC). The approach introduced in the current Science study combines computer-assisted modeling, autonomous synthesis platforms and quantum theoretical calculations for characterizing molecules in order to be able to predict suitable material combinations and to test them in an automated fashion.

“What is the best way to find new materials for photovoltaic components that already have the optimal properties for this application?” This is the question that FAU EAM member Prof. Christoph Brabec, speaker of the FAU Profile Center Solar and Chair of Materials Science and Engineering, has spent over one year exploring together with 22 researchers from the disciplines of chemistry, materials science and engineering, computer science and electrical engineering.

“Until now, we have had two options for finding suitable molecular connections for photovoltaic components: Either using purely digital methods that virtually synthesize the required components in order to find the optimum properties, or using experiments and filling data libraries with the results,” reports Christoph Brabec. The disadvantage is that both methods are based on trial and error. They require a lot of effort and manpower, and are inefficient as a result. The human ability to recognize patterns in huge, complex data sets is limited.

Hybrid approach

The researchers decided on a hybrid approach: They used models from machine learning and trained them with data gained from experiments and from computer simulations in order to be able to predict molecular structures and properties for components that were likely to provide optimum performance. Approximately 100 molecules was all that they needed. After pinpointing the molecules, they started to make improvements. In the first round, the algorithm suggested 24 molecules, which the team then synthesized and tested. It turned out that they are already better than current references. This was verified in a second optimization round. The most powerful material candidates achieved rates of effectiveness reaching up to 24 percent, exceeding the reference values to date by 22 percent.

Automated sample testing

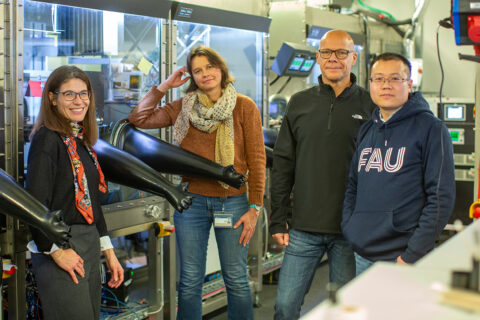

(image: FAU/Anna Tiessen)

High throughput screening has a central role to play. This involves automated laboratory systems that prepare, dose and measure a large number of samples at one time. This procedure is not only more precise, it reduces the length of time taken by the research procedure and minimizes human error. In future, it will be possible to search through material libraries with millions of molecules in no time at all and to discover candidates optimally suited to the required function of the component. “The new approach not only allows us to search systematically but also to limit the scope of the search. The newly discovered chemical compounds can also be optimized and tested regarding required material properties,” explains FAU EAM member Prof. Dirk Guldi, Chair of Physical Chemistry and also speaker of the Profile Center FAU Solar.

Deeper insights

A further effect: The researchers can dive deeper into material sciences. Until now, chemists have been able to reach conclusions regarding the properties of an individual molecule based on its structure. If it is incorporated into a component, however, it is difficult, as the prediction of how well a solar cell will perform depends on many parameters. “Our approach allows new insights into structure-property relationships between a molecule and the actual performance of a component. This means that we now have an algorithm that we can ask ‘Which input parameters are relevant for the performance of the solar cell?,’” explains Christoph Brabec enthusiastically. “We assume that this technology will develop beyond the scope of solar energy to drive innovation in further sectors that are interested in developing new materials using high throughput processes.”